Product description

H frame automatic pullet cage

This system are made up by the hot dipped galvanized cages, automatic feeding & drinking, manure removal and climate control system, it is widely used in close house, it helps the farmers to get best rearing effect because of all chicken rearing period will be controlled by automatic systems with high automation

Brief introduction

Rears baby egg laying chicken from one day old chicks, after 12 weeks or 16 weeks it grows up and near egg laying time, farmers will transport them to egg laying chicken cage also named layer cage, finish the whole rearing processing

Specification

Detailed introduction

Cage system

The bottom wire mesh has the measures 10*10 mm, therefore, it gives the possibility to put day old chicks on the bottom mesh without any extra plastic accessories. The cage designed for maximum comfort and high efficiency

There are feeding holes coupled with the feed troughs for starting rearing period, and the holes’ height can be adjusted to higher level with the pullets growing, very easy to operate

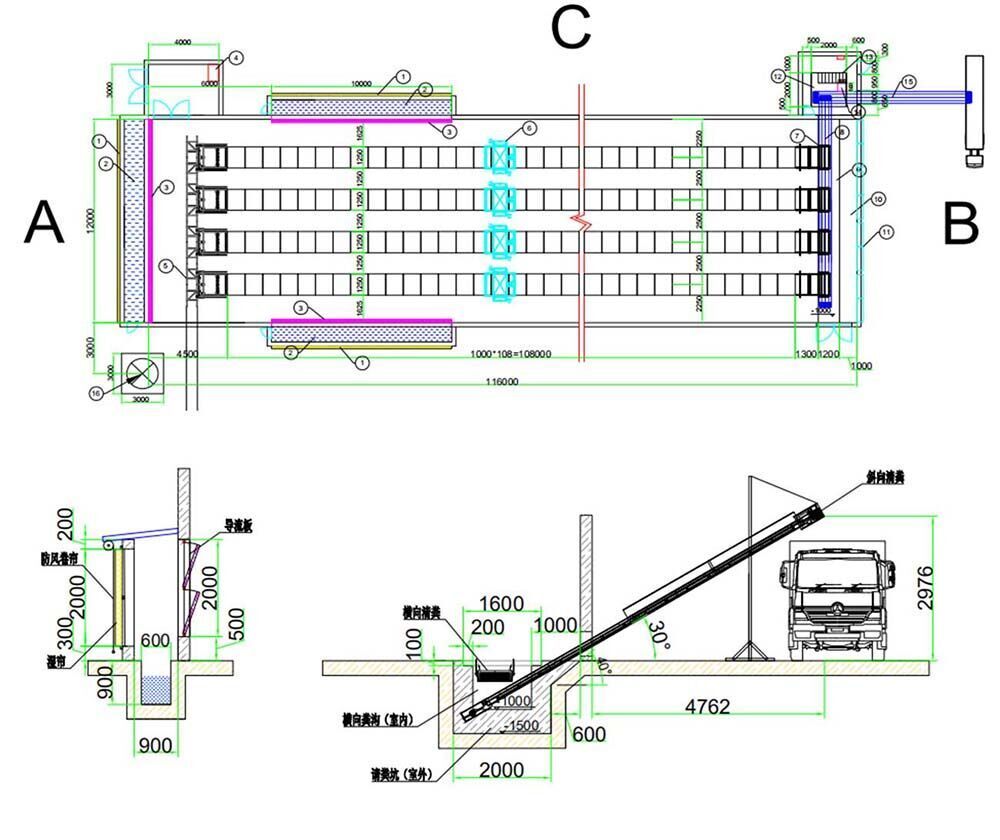

Pullet house climate control system

The pullet chicken house are very strict to the temperature, therefore, we use the good box or cone fans and cooling pads in summer season and heaters(from Holland) to control temperature and give the pullet birds good feeling while rearing

The climate system automation control panel is made up by the different panels, including automatic climate control panel; Internal connection in the board and other installation; pad engine protectors and contactor; flap engine protectors and contactor for the climate system, it is same climate system as the H frame layer cage system

For the flap, PVC paneled in metallic frames air direction covers; The flaps are assembled in front of the pads and with the same length like the pads through the building, so the air will not flow directly on the chicken, it will flow to the roof. In this way spirinkler cooling in the chicken house can be ensured

Drinking system

The main component of the water line: DOSATRON medicators from France, water filters, water pressure regulator, water pipe and drinking nipple, etc

The stainless steel nipple drinker in line is hanged by steel ropes which can be adjusted in height centrally according to the growing size of the birds. thus, an adequate water supply is provided from day one, the steel ropes was fitted on the two end of the cage lines in order to adjust with convenience

There are 2-3 nipples with drip-water cup in each cage. The number of nipples/cage can also be increased as pullets growing. The pressure regulator can keep the pressure on each nipple equal

Automatic feeding system

In this system, feed is distributed automatically to the feed carts from the feed silos by the spiral augers located in a pipe with 90-150 mm diameter, the Augers materials made in South Africa, also the best quality worldwide

Chain feeding system also can be equipped in this cages, the chains also same quality as we import them from South Africa, it is optional by farmers

Manure removal system

It is same design as the H frame layer cage system, manure is cleaned and discharged by the PP manure belts, the chicken manure will delivered to the end of the house, and cleaned by the scrapers

And then the horizontal manure conveyor and the vertical manure conveyor can work together to clean the chicken manure outside of the farms

Electricity control panels

Electrical control panel for feeding system: The electrical installation and control board of feeding system consist of stop switches taking part on top and bottom parts, control cables and timer; the panel for manure removal system: these buttons are featuring sealed and self protection system of engines. It is consisting of protective circuits and fuses of 2 pieces of engines with reducers of horizontal and vertical manure conveyors

Farm application

37632 birds

4 tiers cages are installed

House size is 80m*13m*3.5m

49 units of cage per line

47040 birds

4 tiers cages are installed

House size is 80m*13m*4m

49 units of cage per line

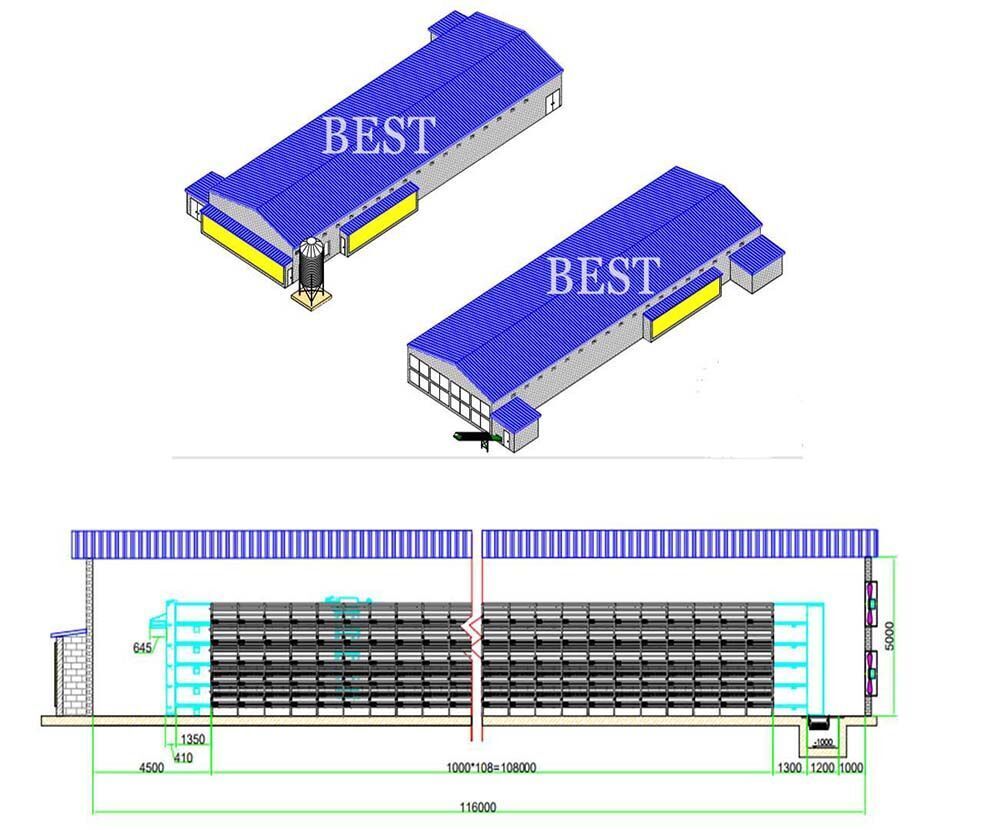

How the layout of chicken cage and poultry equipment will be done as your land?

According to yourl land size, drawing of Poultry house and layout of chicken cage and poultry equipment

How to choose right chicken cage or poultry equipment for your farm?

1. From 1000 birds to 20000 birds

Either manual type or A type is okay, beside chicken cage, we advice you choose manure removal system, chicken dropping cleaning once a day or two days, keep poultry house cleaning and air fresh, reduce disease and improve egg production rate. Some farmers also make feed themselves and order feed crusher and mixer, manure drying machine

2. 20000 birds to 50000 birds

Either H type or A type is okay, large one should consider some automatic equipment, 1 or 2 person manages a house, auto feeding hopper, manure removal system, feed mill and manure drying machine too

3.More than 50000 birds

H type is the most suitable for Turnkey farm project with full automatic equipment such as automatic feeding, manure removal, manure dryer, feed mill line and so on

Certified

Message

Products recommended