Product description

H frame automatic broiler cage

It is designed that when harvesting the broiler chickens, the floor mesh will be taken out and the chickens dropped down on the manure belt and deliver to the end of the chicken house, the transverse broiler conveyor system will deliver the broilers outside of the chicken house, this system including automatic feeding, drinking system, manure collection system and climate control system in close house. It has been designed for maximum profitability and to reduce the overall production cost

Brief introduction

More chickens can be reared, compered with floor raising system, the broiler quantity can be increased by 50% ~ 100% in same house, significantly increased utilization of the house surface area, reduced energy consumption

Manure is isolated from the chicken body completely, reduce the dust greatly, the chance of infection diseases through the feces is less, improve the survival rate of chicken. The exercise of chicken is limited, small energy consumption, save the feed

No bedding needed, save the cost and cleaning; low broken rate, and more cleaner, reducing the chicken's disability greatly and the labor requirements

Very hygienic growing conditions, healthy, uniform flock, increased growth rate, improving feed conversion, up to one crop more per year is possible

Easy cleaning, reduce time, improve working efficiency, avoid the hen house affected by environmental pollution

Specification

Length: 3000mm width: 1820mm height: 765mm

Detailed introduction

Cage frame system

Hot galvanized wire parts provide a high corrosion protection and a long service life. Spring door can be opened simply and easily the bird area is easily accessible for inspection purpose and quick and easy moving-in. It also has the advantage of smooth surface, good elasticity, high strength, low broken rate etc

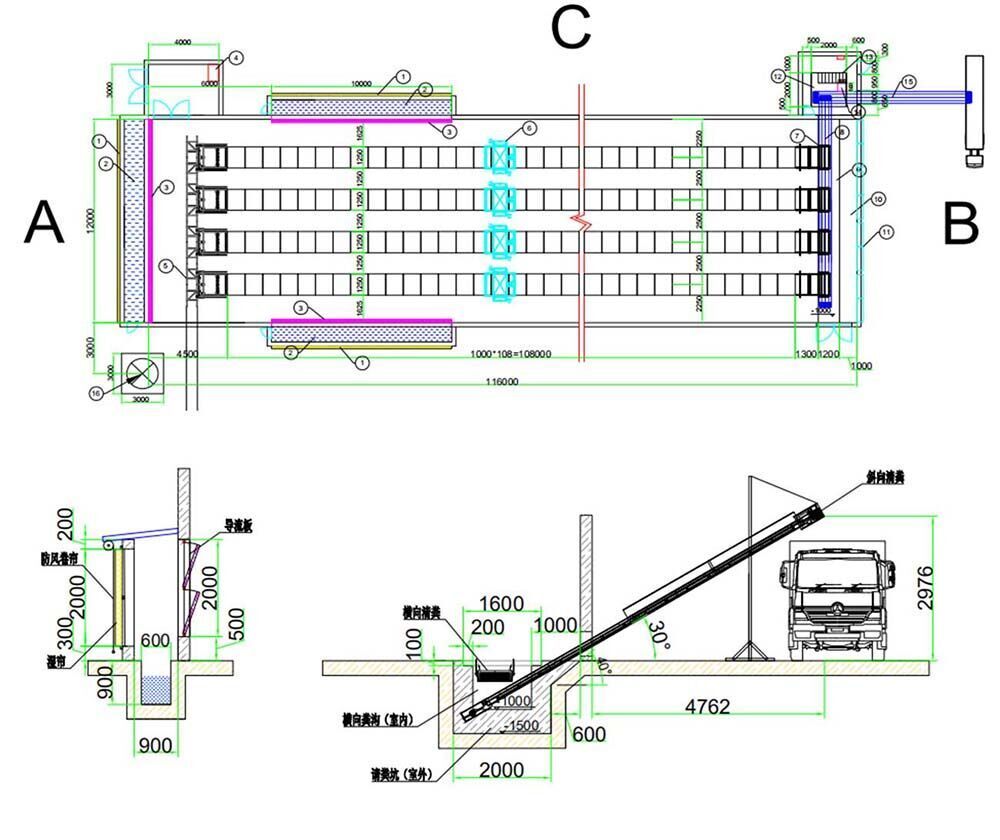

When you harvest the broiler chickens, the floor mesh(drawer dimension is depth 854 * length 708 * thickness 50mm) will be taken out and the chickens dropped down on the manure belt and deliver to the end of the chicken house, the transverse broiler conveyor system will deliver the broilers outside of the chicken house

The push-pull plastic net can be pushed and pulled easily and also can move out of the ready-for-slaughter broilers easily. Its convenient for observing, grouping or selecting and eliminating chickens, and there have enough position for chicken to gather the food and water, the degree of uniformity and health situation are both better

It is the 3 or 4 tiers of this system are most popular. The dimension of each cage cell is 854*708*420mm, and 10 birds in each cell, average 605 sq. cm, can be taken by each bird, this is enough for broiler from day 1 to its harvest. And the farmers can put more or less broilers according the its rearing period

Automatic bird-harvesting

Farm Application

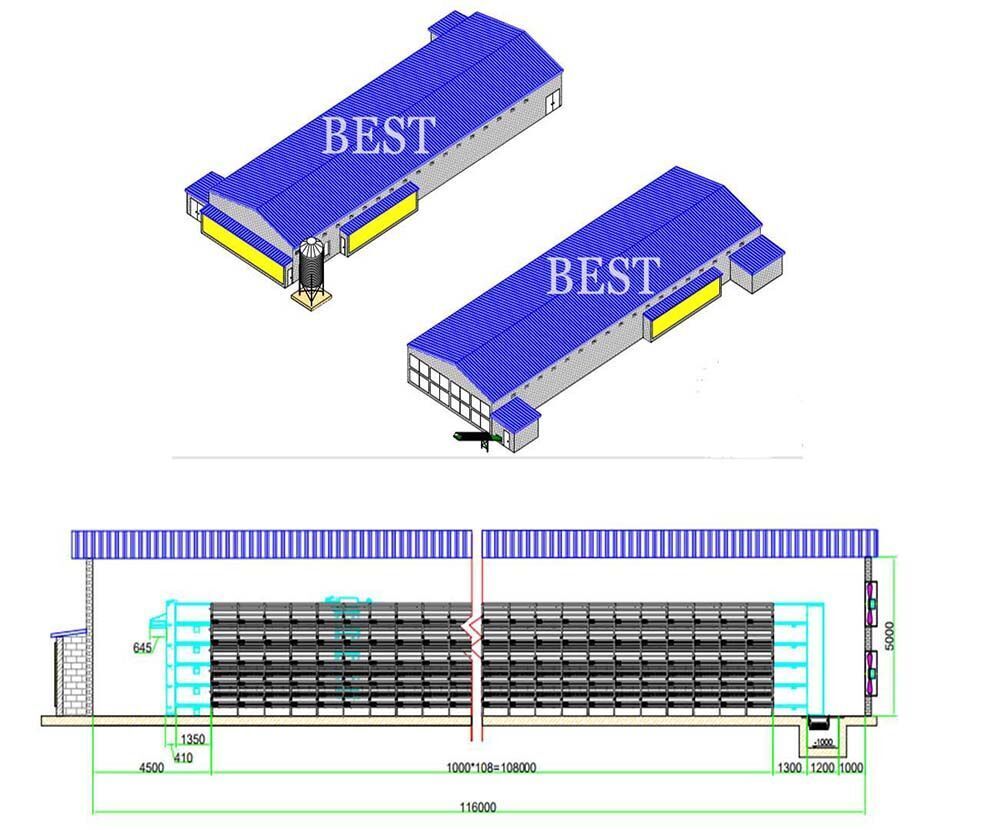

59400 broilers

Poultry house: 97m*20m

Side wall: 4.0m(H)

3 tier cages are installed, 30 units of cage per line

79200 broilers

Poultry house: 97m*20m

Side wall: 4.5m(H)

4 tier cages are installed, 30 units of cage per line

How the layout of chicken cage and poultry equipment will be done as your land?

According to yourl land size, drawing of poultry house and layout of chicken cage and poultry equipment

How to choose right chicken cage or poultry equipment for your farm ?

1. From 1000 birds to 20000 birds

Either manual type or A type is okay, beside chicken cage, we advice you choose manure removal system, chicken dropping cleaning once a day or two days, keep poultry house cleaning and air fresh, reduce disease and improve egg production rate. Some farmers also make feed themselves and order feed crusher and mixer, manure drying machine

2. 20000 birds to 50000 birds

Either H type or A type is okay, large one should consider some automatic equipment, 1 or 2 person manages a house, auto feeding hopper, manure removal system, feed mill and manure drying machine too

3.More than 50000 birds

H type is the most suitable for Turnkey farm project with full automatic equipment such as automatic feeding, manure removal, manure dryer, feed mill line and so on

Certified

Message

Products recommended