Product description

A frame automatic pullet cage

It is designed for pullets which bird age(rearing period) is from day to day 120 old. This system also can be equipped with automatic feeding, drinking, manure removal and climate control system. It is more popular using in tropic country because it is just working well in open house without climate control system. If it used in close of temperate area, the ventilation and heating system are vital to the pullets

Specification

Detailed introduction

Cage system

Each unit dimension of the pullet cage is 1950*500*(350--400)mm, 3 cells per unit, with 9-10 birds per cell, each cell dimension is 650*500*(350-400)mm, so each birds can get 390--433 sq.cm, at least within 17 weeks

Bottom net is densely welded together, the plastic cushion which put on the bottom cage mesh can protect the pullet feet and make them more comfortable

Both the pullet cage meshes and cage support leg frames are processed by hot dipped galvanization because this system usually working 3 recycles per year and most of them working in high temperature and humidity houses;

Raising density per unit area can increase 50% - 100% compared with flooring system and the possibilities of infection diseases caused by manure decrease, therefore, death rate is minimized because invariable birds in each cell of cages, and then it is also convenient for observing growth condition of birds, grouping and selection

Amount of exercise is small, therefore, more feed is saved by the professional pullet feed trough the adjust board which can be improve inside height with the pullet growing

Comparing with the floor raising system, the padding cost for flooring system is deducted, dramatically reduces birds disability

Drinking system

It is made up by the square pipes(thickness 2.5mm) or round pipes(thickness 2.0mm) with 360 degree flowing nipple

drinkers, water drip cups and water pressure regulators, terminals, splits, water filters makes sure the water is clean

The drinking system can be automatic nipple drinking line and manual feeders and drinkers for first two weeks while the pullets are too small to get water nipple drinkers

The pipes can be adjusted in higher level as pullets growing bigger day by day because the grid meshes has empty design in the middle place to adjust the pipes going up to higher level

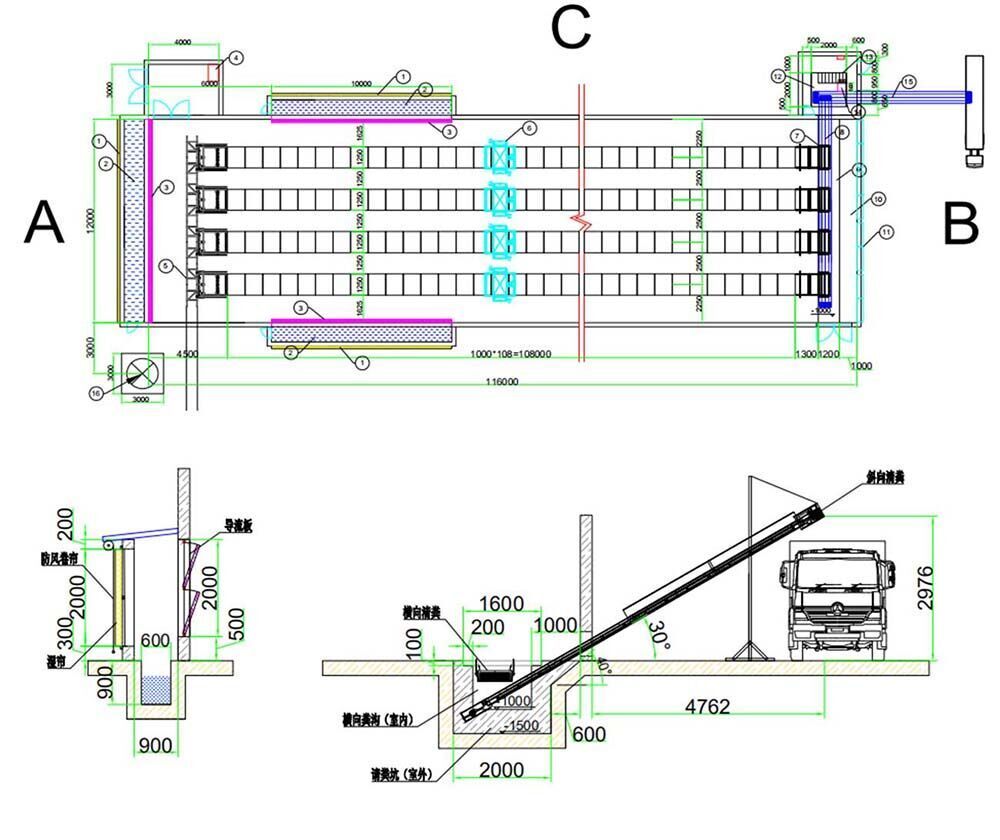

Automatic feeding system

Both of the traveling hopper(feeding carts) type and chain feeding system are available. The augers and chain materials made in South Africa, also the best quality worldwide

The feeding cart connected with the silo by the transverse feeding auger is more popular here.In this system, feed is distributed automatically to the feed carts from the feed silos by the spiral augers located in a pipe with 90-150 mm diameter

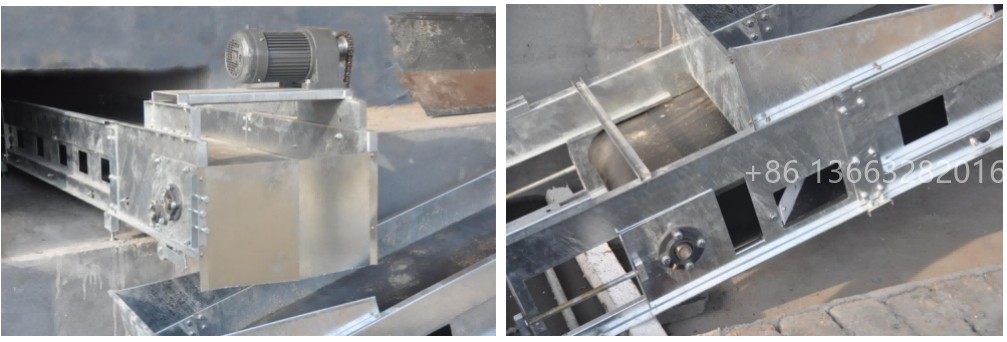

Manure removal system

The 1--3 tier of cages can be fitted with manure curtain on the back of the cage meshes in case of the dropping manure from upper tiers

Manure belt system or manure scraper in the manure pits to collect the chicken manure outside of house; the A frame pullet cage system also can be equipped with the manure belts system under the cages which can work together with the manure conveyors

Electricity control panels

Electrical control panel for feeding system: The electrical installation and control board of feeding system consist of stop switches taking part on top and bottom parts, control cables and timer; the panel for manure removal system: these buttons are featuring sealed and self protection system of engines. It is consisting of protective circuits and fuses of 2 pieces of engines with reducers of horizontal and vertical manure conveyors

Farm application

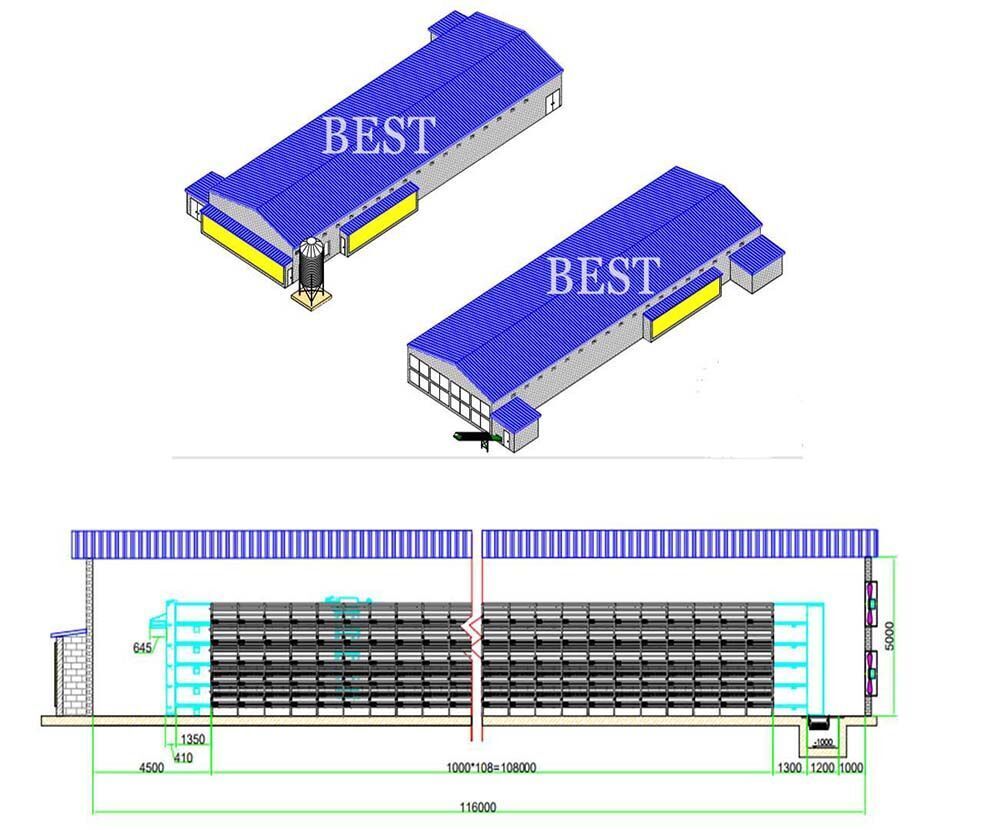

How the layout of chicken cage and poultry equipment will be done as your land?

According to yourl land size, drawing of poultry house and layout of chicken cage and poultry equipment

How to choose right chicken cage or poultry equipment for your farm?

1. From 1000 birds to 20000 birds

Either manual type or A type is okay, beside chicken cage, we advice you choose manure removal system, chicken dropping cleaning once a day or two days, keep poultry house cleaning and air fresh, reduce disease and improve egg production rate. Some farmers also make feed themselves and order feed crusher and mixer, manure drying machine

2. 20000 birds to 50000 birds

Either H type or A type is okay, large one should consider some automatic equipment, 1 or 2 person manages a house, auto feeding hopper, manure removal system, feed mill and manure drying machine too

3.More than 50000 birds

H type is the most suitable for Turnkey farm project with full automatic equipment such as automatic feeding, manure removal, manure dryer, feed mill line and so on

Certified

Message

Products recommended